Laser process development for industry and research

The precise processing of materials using lasers is one of the key processes of modern manufacturing.

As the Bavarian Laser Center, we develop for our customers individual and high-precision laser processes – from prototype to series production.

Our services in process development

Processes that enable precise solutions.

Our service portfolio ranges from welding and cutting to structuring using laser radiation. Another key focus at the Bavarian Laser Center is laser-based additive manufacturing. The material being processed is of secondary importance. experienced staff knows how to design the processes.

Feasibility studies & small series production

We support our customers from the initial trial to a production-ready process. In doing so, we combine application-oriented research with industrial feasibility.

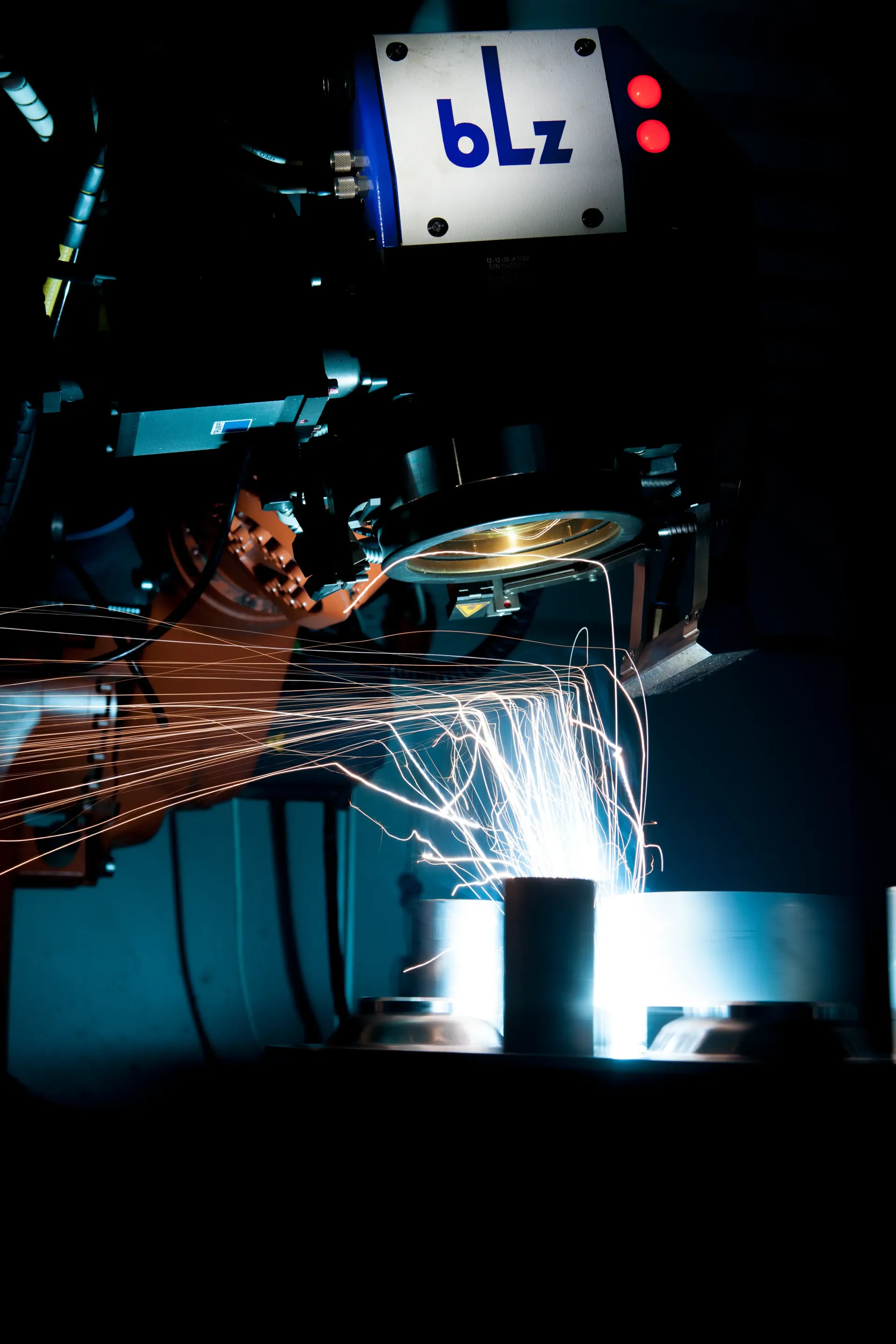

Laser beam welding

Laser beam welding enables highly precise joining of joints – from electromobility and shipbuilding to aerospace. The material is hardly a factor: we weld metals, polymers, ceramics, and glass.

Battery cell welding

Battery cell contacting is crucial for electromobility – and despite the high risks, it's our specialty. With years of experience, we have mastered cell contacting, from individual cells to entire module assemblies.

Laser beam soldering

Laser beam (hard) soldering is ideally suited for use in temperature-sensitive assemblies. Localized energy input allows for the creation of joints with sufficient strength.

Laser beam cutting

Not every semi-finished product has the perfect dimensions, and not every material can be efficiently processed mechanically. Our portfolio of laser systems – whether pulsed or continuous emission – enables us to cut a wide variety of workpieces using lasers. This allows us to cut both sheet metal and the thinnest films.

Micro- and nano-processing

The potential of micro- and nanomachining lies in creating high-performance surfaces through cleaning, structuring, or ablation. Furthermore, we can produce highly precise cuts and join films. This improves the final performance of a product or minimizes waste along the process chain.

Additive manufacturing - Laser powder deposition welding (DED)

Laser powder deposition welding is ideally suited for coating, repairing, and even creating three-dimensional geometries. We are not limited to metallic materials; we also process ceramics and polymers. Combined with beam shaping, we challenge the materials – not the other way around!

Additive manufacturing - Laser melting from powder bed (PBF)

Laser beam melting enables the production of components with complex geometries – a unique feature of this technology. With our many years of experience in additive manufacturing, we can assist with potential assessments or quickly produce components that would otherwise have significantly longer lead times (e.g., tools).

Laser hand welding

Laser manual welding is increasingly becoming an industrially used technology. We provide fundamental support for all questions related to manual welding – from operator safety and operation to achievable quality.

Get individual advice now

Are you planning a project or do you want to know if laser technology is suitable for your project?

Contact us – we'd be happy to advise you.

Benefits for industrial partners - process development

A large number of partners from science and industry have already benefited from our know-how in process development They benefited and are more than satisfied with our results. It's time for you to secure a spot on the list as well.

01

Competent

Benefit from our many years of experience in the field of laser material processing.

02

Solution-oriented

We develop the best solution for your requirements or your product. Not necessarily the easiest solution for us to implement.

03

Flexible

Whether metals, plastics, ceramics or glass – we have the necessary system technology and therefore process all materials.

04

Fast

Our biggest advantage over application labs? We're significantly faster. With us, you'll receive concrete results for most requests in less than a week.

Leave your callback request here.

Subscribe to Newsletter

FAQs on the topic of laser process development at the Bavarian Laser Center

How does the development of laser processes proceed at our company? Here you will find the answers to the most important questions.

What is meant by laser process development?

Laser process development describes all necessary steps for the implementation and optimization of laser-based manufacturing processes.

The goal is to process materials – be it metal, plastic, ceramic or glass – efficiently and reproducibly.

What processes does the Bavarian Laser Center offer?

All processes in which the laser is used as a tool, whether welding, cutting or surface processing.

I have a specific request. How soon can we get started?

Once the parameters are clarified, our high flexibility allows us to start and provide initial feedback in less than one working week.

I would like to see the trial live on site. Is that possible?

Of course. We operate with maximum transparency and are happy to offer our customers the opportunity to accompany the trial on site.

Does the Bavarian Laser Center also support the transfer of the process to my company?

We work with commercially available system technology, so a transfer is easily possible. We are also happy to provide on-site support for implementation and validation.